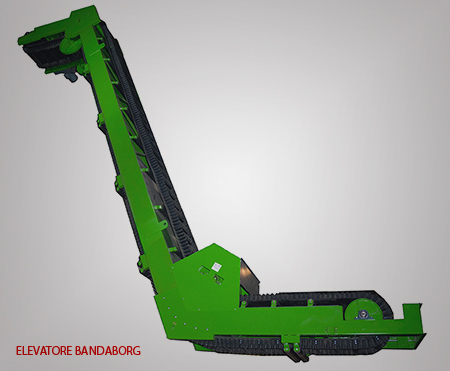

INCLINED BELT CONVEYORS

GVF Impianti's Bandaborg inclined belt conveyors are advisable for all through-and-through or granulated products that have to be transported on inclined sections until 70°.

They are built with solid carbon steel carpentry and guarantee high flow rate because the first part, for the gravitational or dosed load, is flat and that allows a uniform distribution inside the buckets, which are made with anti-cut and anti-oil gummed walls.

A couple of very big sliding wheels, that reduce to the minimum the wear of side sliding tracks, compose the intermediate control system.

The superior neck, equipped with an unload hopper, allows to place the unload point anywhere depending on the plant needs. This solution is particularly suitable for all fragile or highly abrasive products that usually are unsuitable for bucket elevators transport.

Also Bandaborg inclined belt conveyors are equipped with a control unit consisting of a ratio motor assembled on a carbon steel carpentry seat, connected through a flexible joint to the gummed control shaft drum in order to guarantee the maximum traction effectiveness. The transmission roller is squirrel cage type with female friction cones for the products unload.

The machine can be provided with covers and an aspiration system to depressurize the plant.