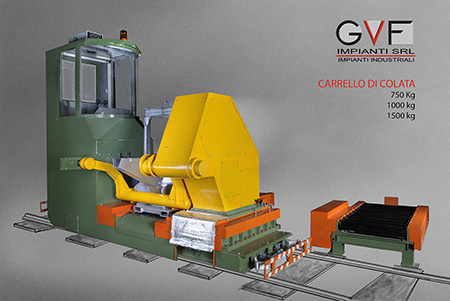

GVF's CASTING CARRIAGE

GVF Impianti's Casting Carriage is built in sizes of 500 – 1000 – 1500 Kg of liquid cast iron and is the result of a 30 years experience in casting systems. Casting Carriage main feature is the total security and the maximum precision during the operations, which increases significantly the operator's comfort and the entire line's productivity. Casting quality increase, productivity increase, result constancy, comfort and security are its strengths.

GVF Impianti's Casting Carriage "OIL FREE"

OPERATIONAL SECURITY

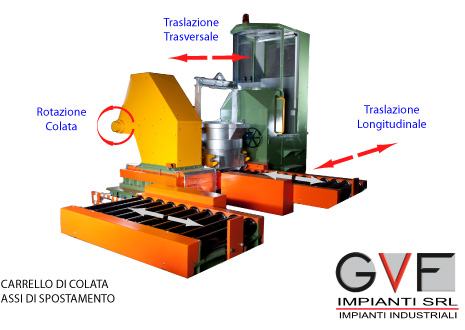

One of the Casting Carriage peculiar features is that no oil is needed to make any movements. The machine uses Brushless engines technology to assure incomparable movement precision and fluidity. The entire system is managed by software, GVF Impianti home made, that permits to handle the engines and the angular and linear commands with a joystick from the bridge deck. Specific attention is dedicated to security, both active and passive, of the staff operating in the working area, with barriers inside the bridge deck and on the moving axis of the carriage; also are provided sensors and position reed in order to prevent accidental pouring.

ERGONOMICS AND PERFORMANCES

The higher position of the bridge deck allows following with safety and precision all the operative phases, permitting the casting while the line is moving. The movement on every axis also permits to reach easily all the casting points. The speed of the movements, in proportion to the action of the joysticks, allows movements as fast as precise, accelerations and decelerations with fluidity unknown on any other casting system. The presence of two roller conveyors, one for the loading and one for the ladle downloading, permits to always keep feeded the Casting Carriage. If you put money in an efficient moulding system, then you have to equip it with an innovative casting system: GVF Impianti's Casting Carriage.

The Casting Carriage can be equipped with a holding furnace loading system totally automatic, which it brings three ladles inside the circuit in order to guarantee continuously the presence of liquid cast iron and very high productivity levels for the system.

We can also realize the carriage with a fixed casting workstation or with double ladle. GVF Impianti supplies the carrel ladles attachable on two sides, manganese steel rails, inoculation and spheroidizing systems, scorifying and pouring abutment, providing a full service, for every need of fusion.

|

|

||

|

|||